In the food industry, safety is key – not only for workers, but also for consumers. Ensuring that food production is safe and hygienic requires strict rules and measures to prevent contamination. An often overlooked but essential safety measure is the use of detectable earplugs. This special hearing protection not only protects workers’ hearing in an often noisy environment, but also contributes to food safety and prevents unwanted materials from entering food. In this blog, we take a closer look at the importance of detectable earplugs in the food industry, what makes these earplugs unique and how they contribute to a safe work environment.

What are Detectable Ear Plugs?

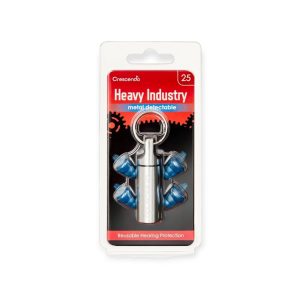

Detectable earplugs are specially designed hearing protectors that not only prevent hearing damage, but can also be easily detected with a detection system. These earplugs are usually made of striking colors such as blue so that they are visually recognizable and often contain a detection bullet made of metal. This bullet is magnetic and allows the earplugs to be detected by metal or X-ray detection systems. This is vital in the food industry, where unwanted materials in products can cause serious health risks and lead to high costs through recalls.

Why are Detectable Earplugs Important in the Food Industry?

The food industry is an environment where safety and hygiene are always paramount. Preventing contamination is crucial, and all processes and products must be carefully monitored. Detectable earplugs play an important role here to ensure that small parts, such as earplugs, do not get into the food undetected.

The benefits of detectable earplugs in the food industry are clear:

- Protection from hearing damage

Workers in food production are often exposed to loud machinery, which can produce sounds above the safe limit of 80 dB. Prolonged exposure to high noise levels can lead to hearing damage and hearing loss, which can have lasting effects. Wearing detectable earplugs effectively protects workers’ hearing without compromising food safety. - Preventing food contamination

In a busy work environment where there is a lot of movement and noise, there is a chance that an earplug could come loose and end up in the production line. Detectable earplugs prevent them from ending up in the food unseen because the detection ball allows the earplug to be quickly located and removed. - Cost savings through recall prevention

Food recalls due to contamination can be costly and can damage a company’s reputation. Using detectable earplugs significantly reduces the chance of undetected contamination, resulting in reduced risk of recalls and long-term cost savings. - Compliance with legal standards and regulations

Many food processing plants are required by law to take measures to prevent contamination. Offering detectable earplugs to employees complies with these safety regulations and contributes to a safe, responsible work environment.

What is a Detection bullet?

A detection bullet is a small, metal component embedded in detectable earplugs. This bullet makes the earplug easily detectable by detection systems such as metal or X-ray detectors. When an earplug accidentally becomes dislodged and enters the production line, the detectable bullet can be quickly detected and removed by the embedded detection systems. This makes detectable earplugs a valuable prevention measure in any food production facility.

Thus, the detection ball provides double assurance: hearing protection for employees and food safety for consumers. Thus, this technology contributes to a more efficient and safer working environment, preventing hearing problems and contamination in the final product.

How Do Detectable Earplugs Work in Practice?

In practice, detectable earplugs are easy to use. Like regular earplugs, they are inserted to reduce harmful noise levels, but they are also designed to remain comfortable and secure in the ear canal. The use of striking colors, such as blue, allows employees, supervisors and inspectors to easily visually identify them. This makes it easier to verify that everyone in the workplace is wearing the proper hearing protection.

When using detection systems such as metal detectors on the production line, the earplugs will be detected when they unexpectedly enter the production process. This rapid detection prevents contamination from entering the finished products, ensuring food safety.

Hearing Safety in the Food Industry

Hearing loss from noise in the workplace is a real risk in the food industry. Machinery, conveyors and other equipment produce sounds that often exceed recommended safe noise levels. While not every workplace in the food industry is equally loud, long-term exposure to noise without protection can put workers at risk of permanent hearing damage. Detectable earplugs protect employees’ ears from hearing loss and other noise-related health issues without increasing the risk of food contamination.

Regular monitoring and hearing protection are therefore of great importance in the food industry. Detectable earplugs are a simple and cost-effective solution to protect workers’ health while also reducing the risks of food contamination.

Tips for Using Detectable Ear Plugs

As an employer in the food industry, it is important to maintain both safety and hygiene in the workplace. Here are some tips to ensure that detectable earplugs are used to their best advantage:

- Provide adequate supplies: Provide all employees exposed to noise with detectable earplugs and ensure that there are always enough available.

- Train staff: Explain why detectable earplugs are important and how they contribute to both personal safety and food safety.

- Check regularly: Provide regular inspections to see if everyone is wearing the earplugs correctly.

- Choose the right size and fit: Comfortable earplugs stay in place better and provide more hearing protection. Therefore, choose earplugs that fit the employees’ anatomy.

Detectable Earplugs at Horend Goed

As specialists in hearing protection, detectable earplugs should of course not be missing from our range. You can find them in our webshop.

Conclusion

Detectable earplugs are a smart and effective solution for the food industry, where safety and hygiene are non-negotiable. These earplugs offer dual protection: they protect workers’ hearing in noisy work environments and reduce the risk of food contamination through a detectable bullet. This allows food production companies to ensure a higher level of safety, both for their employees and for the consumers who use their products.

Detectable earplugs make it possible to combine health and safety in the workplace with the highest standards of food safety. This simple but clever innovation is a step forward for companies that value a responsible and safe working environment.